Features

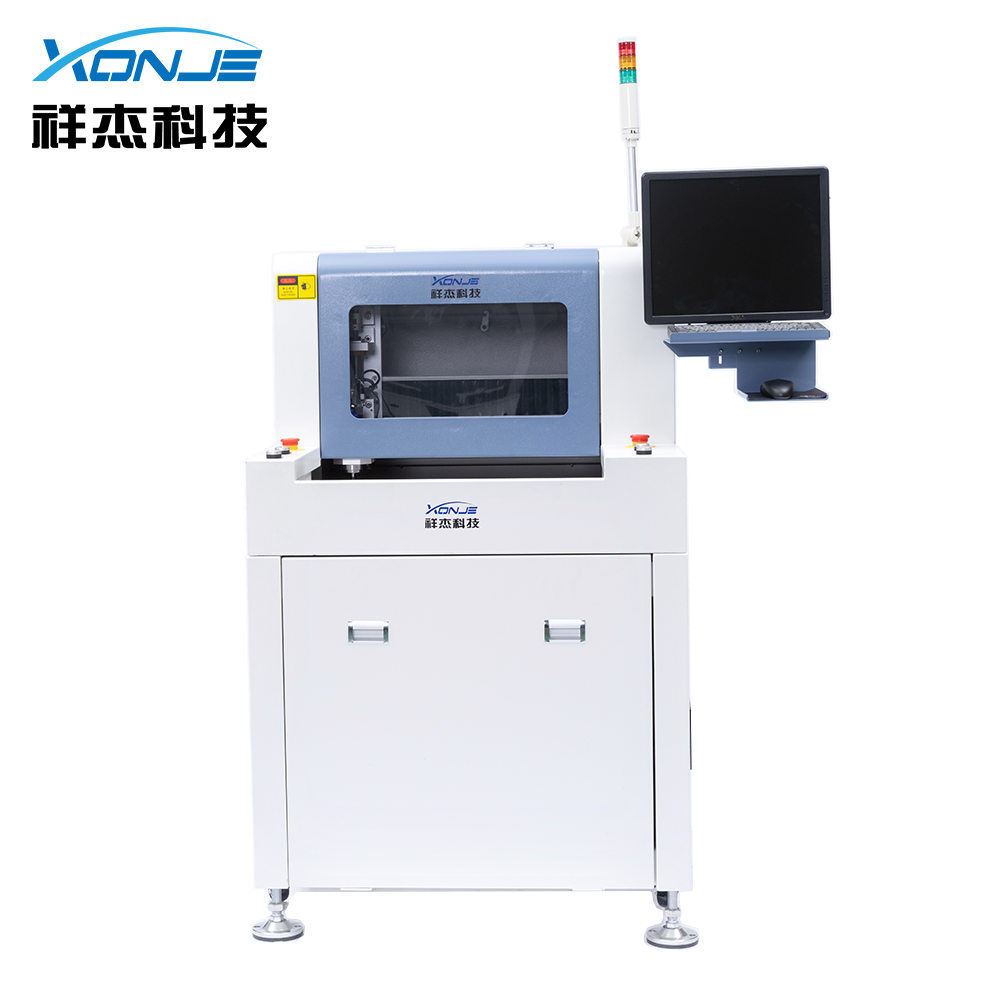

XJ-800 series mainly uses the high-speed operation of milling cutter, dual platform four-axis servo drive to separate the multi connected PCB, according to the pre programmed path, replacing the manual breaking or V-CUT or push cutting defects, stress damage, improving product quality and reducing scrap rate. The machine adopts man-computer interface and AC servo motor.

WIN7 system operating interface. It uses high-pixel CCD production program to teach and edit the cutting path. It can be modified and simulated in a single step. It uses two servo moving platforms. As a PCB exchange device for upper and lower substrates, it can effectively reduce the idle time of the machine, thereby achieving higher production efficiency and quality. The software has MAKE compensation, same workbench duplication, double workbench duplication, equipped with large, medium and small three windows for more precise programming, adding a rectangular frame on the basis of the original target, programming is more intuitive and accurate programming, MAKE geometric alignment is automatically captured, The two tables are completely independent of parameters. Compared with the traditional three-axis machine, the response is faster, the parameters are more independent, the efficiency is higher, and the cutting accuracy is more guaranteed.

High-speed spindle:

The imported high-speed spindle uses the German SycoTec(Kavo) spindle motor widely used in the industry's high-end splitters. The spindle has a high speed(60000rpm/min), long service life, convenient assembly and disassembly, and a smooth cutting surface without burrs and defects. It is also equipped with the original SycoTec 4424 Spindle frequency converter, which allows the spindle motor to have a longer service life, higher cutting torque, and the lowest temperature rise effect.

Double servo

Servo-driven two working platforms are used to alternately process and place PCB substrates, reduce waiting time,increase production capacity, and solve the accuracy problem of the cylinder-driven platform.

Visual system:

High-pixel color CCD and large magnification lens can assist program teaching and editing simulation functions. The automatic MARK positioning and correction system improves the cutting accuracy and prevents the board from being damaged due to the board not being in place. It is faster to copy left and right programs and switch models. Optional barcode reading function to realize 1D/2D barcode reading and save or upload, which is convenient for traceability and digital management.

Vacuum method:

Exclusive built-in vacuum cleaner, the fifth-generation design makes the overall effect of the equipment beautiful and concise space, beautifies the overall effect of the workshop, flexible movement, convenient placement and maintenance. Shorten the vacuum path and improve the vacuum effect,with good airtightness and low noise. The dust bag can be cleaned andreused, reducing production costs!

Safety light curtain:

The Japanese original KEYENCE safety grating is selected to protect the operating safety of operators and avoid accidents.

Technical parameter

XJ-800 technical parameters

XJ-800L technical parameters

项目project

技术参数technical parameter

项目project

技术参数technical parameter

XYUZ运动范围XYUZ range of motion

730MM*450MM*450MM*50MM

XYUZ运动范围XYUZ range of motion

875MM*620MM*50MM*50MM

单工作台切割范围Single table cutting range

330MM*360MM*50MM

单工作台切割范围Single table cutting range

420MM*520MM*50MM

丝杆/导轨Lead screw / guide rail

HIWIN丝杆导轨

HIWIN screw guide

丝杆/导轨Lead screw / guide rail

HIWIN丝杆导轨

HIWIN screw guide

定位精度positioning accuracy

±0. 01mm

定位精度positioning accuracy

±0. 01mm

伺服系统servo system

四轴伺服电机Four axis servo motor

伺服系统servo system

四轴伺服电机Four axis servo motor

主轴principal axis

祥杰/KAV0S (选配)

XONJE/ Kavos (optional)

主轴principal axis

祥杰/KAVOS (选配)

XONJE/ Kavos (optional)

主轴变频Spindle frequency conversion

高速变频器

High speed frequency converter

主轴变频Spindle frequency conversion

高速变频器

High speed frequency converter

主轴转速Spindle speed

2000rpm/min~60000rpm/min

主轴转速Spindle speed

2000rpm/min~60000rpm/min

主轴刀具Spindle tool

0.8mm~3mm

主轴刀具Spindle tool

0.8mm~3mm

控制主机Control host

工业电脑Industrial computer

控制主机Control host

工业电脑Industrial computer

切割速度Cutting speed

1mm/sec~100mm/sec

切割速度Cutting speed

1mm/sec~100mm/sec

切割功能Cutting function

可执行直线,圆弧,圆的切割

It can cut straight lines, arcs and circles

切割功能Cutting function

可执行直线,圆弧,圆的切割

It can cut straight lines, arcs and circles

静电处理Electrostatic treatment

静电消除器Electrostatic eliminator

静电处理Electrostatic treatment

静电消除器Electrostatic eliminator

集尘方式Dust collection mode

可选下集尘或上集尘Optional lower dust collection or upper dust collection

集尘方式Dust collection mode

可选下集尘或上集尘Optional lower dust collection or upper dust collection

扫码MES功能Code scanning MES function

支持(选配)

Support (optional)

扫码MES功能Code scanning MES function

支持(选配)

Support (optional)

集尘机尺寸Size of dust collector

1050mm*800mm*550mm

集尘机尺寸Size of dust collector

1050mm*800mm*550mm

电源功率Power supply power

三相五线380V3kw (含集尘器)Three phase five wire 380v 3kw(including dust collector)

电源功率Power supply power

三相五线380V3kw (含集尘器)Three phase five wire 380v 3kw(including dust collector)

空气压力air pressure

5kg/cm2

空气压力air pressure

5kg/cm2

机台尺寸Machine size

1220mm*1200mm*1850mm

机台尺寸Machine size

1135mm*1400mm*1850mm

机台重量machine weight

680kg

机台重量machine weight

700kg

Contact me

Company : Guangdong Xiangjie Intelligent Technology Co., Ltd.

Address : No.105,Langbei Road,Changhuang Road,Changping Town,Dongguan City,Guangdong Province,China

Zip Code :523570

Email : alanhe@smtxj.com

whatsapp :+86 13650031915

Tel/Skype :+86 13650031915

website : http://www.xonje.com/en/

Facebook :https://www.facebook.com/profile.php?id=100072842804069

Youtube :https://youtube.com/channel/UC9gheGcXnZrYsP3k5PPoqJg