Features

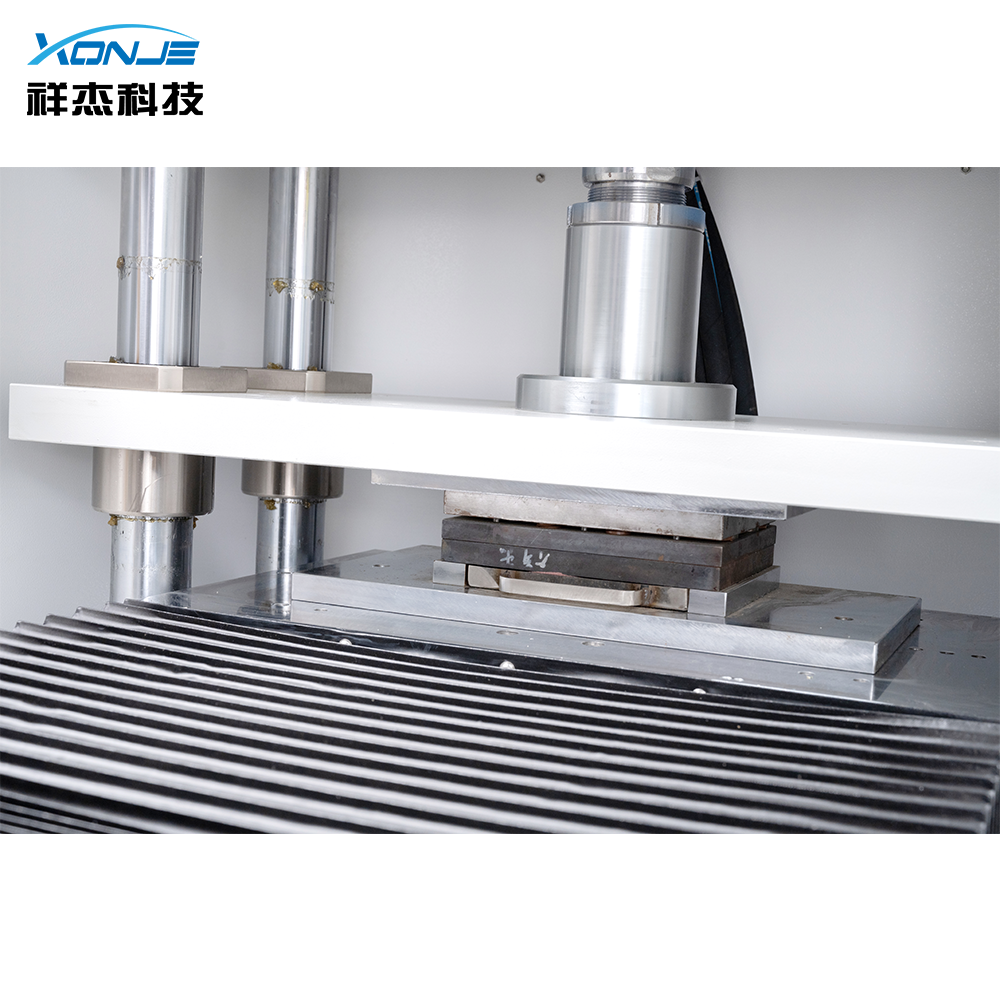

1. Using servo hydraulic punching, the speed is fast, and the cutting speed is 8 seconds per whole piece:

2. It is suitable for cutting all kinds of FPC splicing board connected on the whole surface, with a cutting accuracy of ±0.03mm, the pressing stroke can be set arbitrarily, and it has the function of half-breaking the whole board;

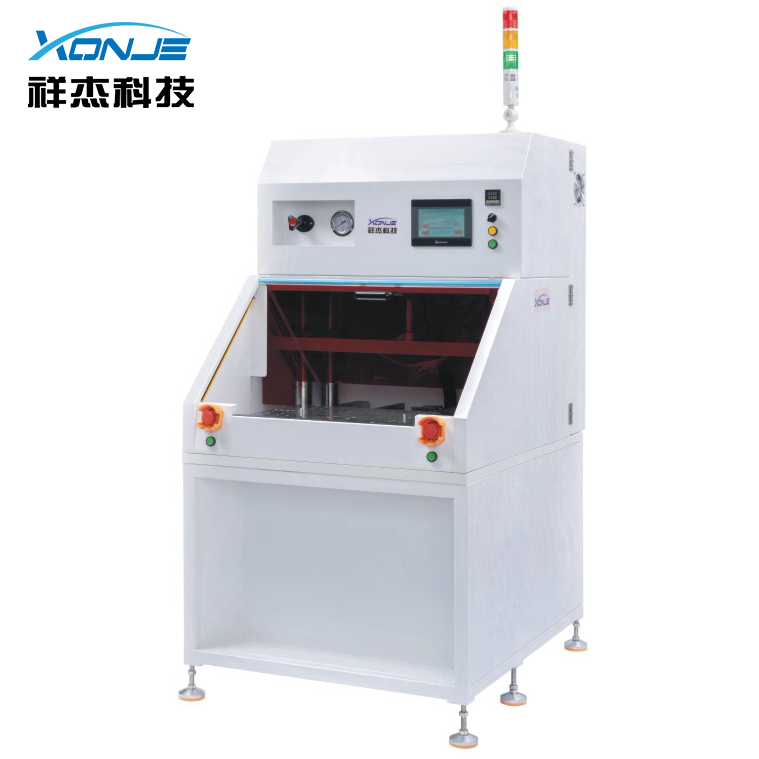

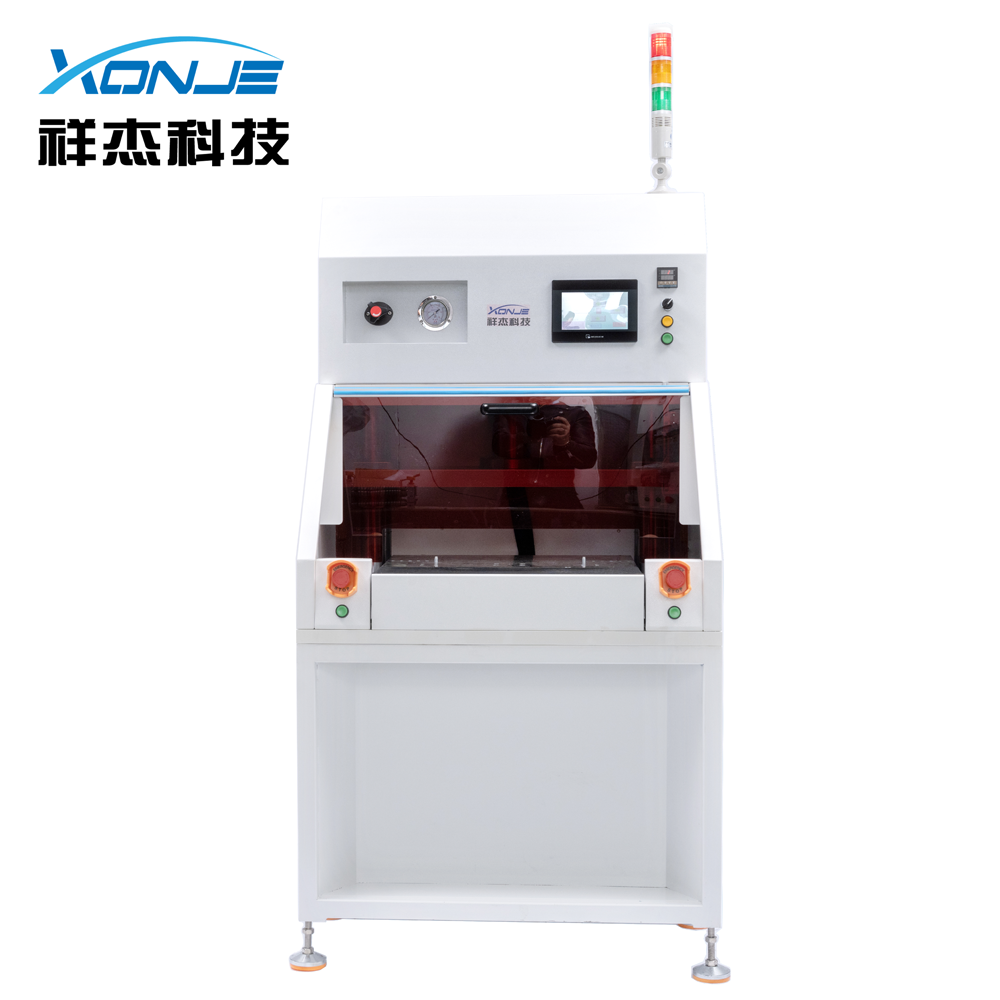

3. Punching pressure is 30 tons, with oil pressure and temperature measurement alarm function;

4. Cutting table size(L*W)460mm*400mm;

5. The sliding accuracy of the platform, the horizontal accuracy of the platform and the mold table is ±0.02mm, composed of servo motors, servo drives, sensors, etc., through the control system to complete the front and rear sliding of the platform, so as to realize the FPC handling function;

6. The maximum die thickness of the die size:T=100mm, which can be cut normally;

7. High-precision guide rods, high-quality oil cylinders, oil pumps, Panasonic motors, multi-oil pipelines, proportional valves, solenoid valves, etc. complete the punching function, Through the control system, the pressure can be fine-tuned, and the downward pressure and cutting can be stable;

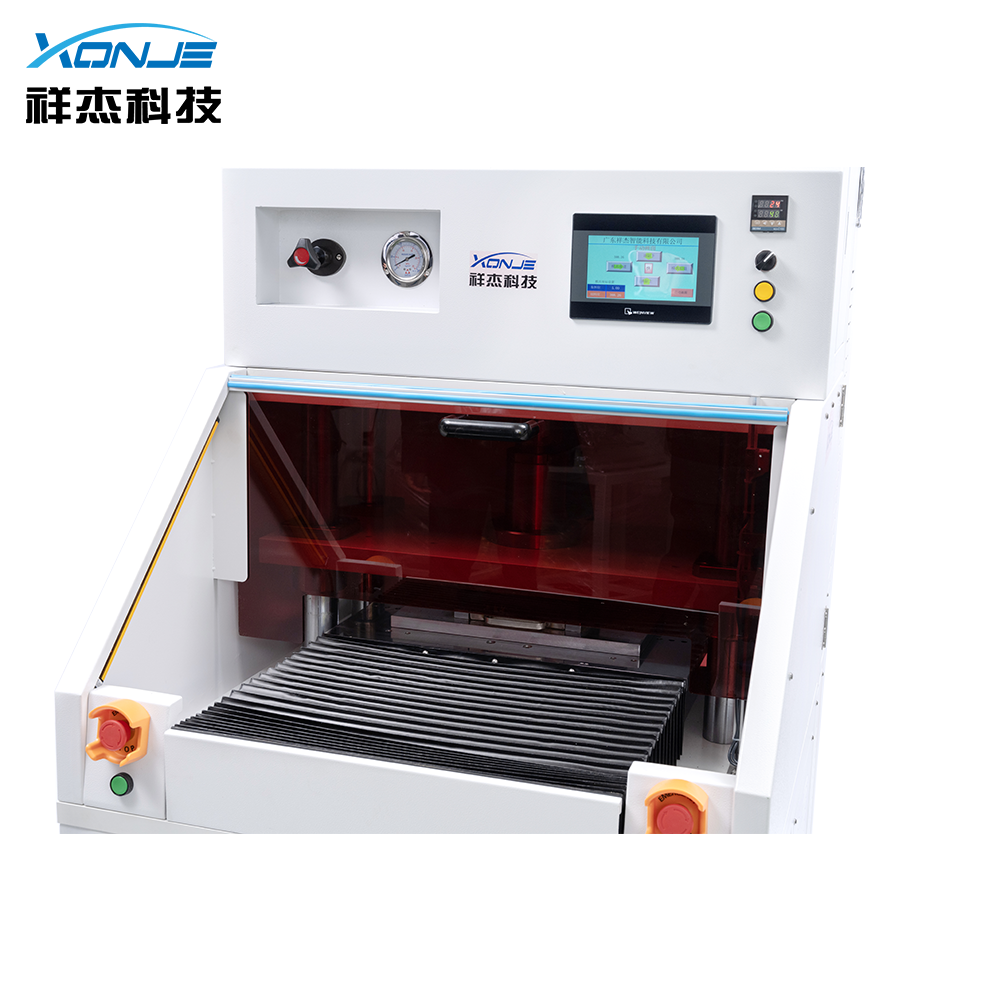

8. Drawer type of cutting worktable(cutting table top automatically returns to the operating position after cutting), using servo motor to drive fast and high precision;

9. The production quantity of the touch screen display equipment can be set arbitrarily: the number of pieces produced by the equipment can be manually set by the user;

(1) The device pressure will display the measured value.

(2) The equipment pressure can be set in the touch screen. When entering the pressure adjustment interface, a non-operator password is required to unlock the parameters to adjust the parameters. The operating area has a safety protection device.

10. Control system

(1) Realize emergency stop under abnormal conditions, and set sound and light alarm

(2) Abnormal situation realizes emergency stop, and set sound and light alarm

(3) Emergency stop buttons and alarm devices are installed at both ends of the equipment

(4) The control panel is locked to prevent unauthorized personnel from modifying and setting parameters

(5) Equipped with an independent power distribution cabinet, the circuit is divided into functional blocks, strong current and weak current blocks , easy to maintain

(6) The system sets up an overload protection system

11. Touch screen

(1) Operation authority can be set, control methods: point touch, manual, semiautomatic, output storage, statistics and error information storage

(2) In the parameter setting(engineer level: setting authority is required),the program(each station)can be selected and set, real-time monitoring, parameter setting and so on.

Technical parameter

工作方式 Operation mode

伺服油压式Servo oil hydraulic system

出力 Force output

25T/30T/50T/80T

面积 Place the board area

350*500MM

使用电压 Use voltage

380VAC

工作气压 Working pressure

0.5-0.7MPA

机器重量 Machine weight

750KG

长*宽*高 L*W*H

1160*910*1800MM

Contact me

Company : Guangdong Xiangjie Intelligent Technology Co., Ltd.

Address : No.105,Langbei Road,Changhuang Road,Changping Town,Dongguan City,Guangdong Province,China

Zip Code :523570

Email : alanhe@smtxj.com

whatsapp :+86 13650031915

Tel/Skype :+86 13650031915

website : http://www.xonje.com/en/

Facebook :https://www.facebook.com/profile.php?id=100072842804069

Youtube :https://youtube.com/channel/UC9gheGcXnZrYsP3k5PPoqJg