Device Configuration

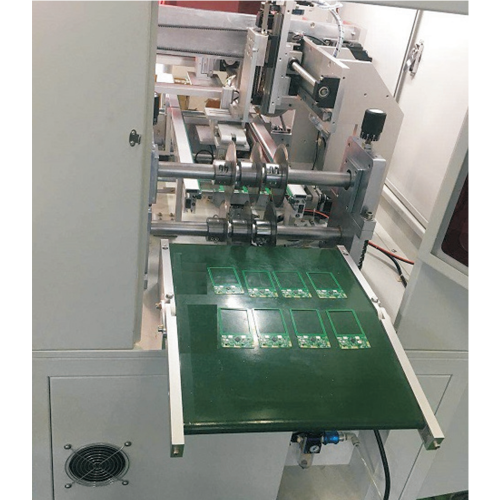

2. It can be equipped with functions such as automatic feeding, automatic cutting, automatic receiving, etc., and the machine operation is simple and fast;

3. The setting of various parameters fully ensure the continuity of board loading and cutting;

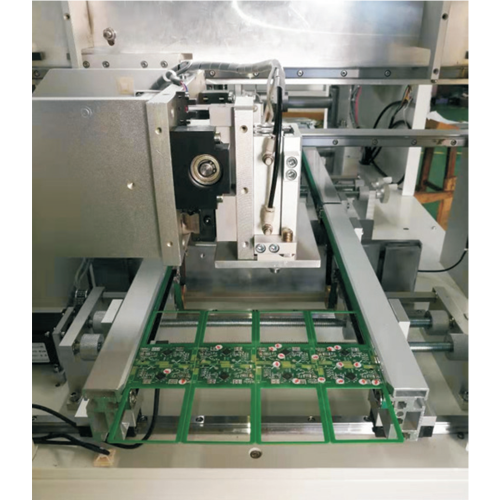

4. The main transmission components adopt precision stepping motors and servo motors, and the pneumatic components adopt international brands, which makes the repeat positioning accuracy high;

5. The whole machine adopts Mitsubishi PLC+WEINVIEW touch screen control,The operation interface is simple and convenient;

6. Equipment working voltage: 220 V 50Hz;

7. Efficiency: 25s/pcs (150*150mm, 4 cuts For reference);

8. The working area is protected by a safety photoelectric switch.

Machine cut-board action description

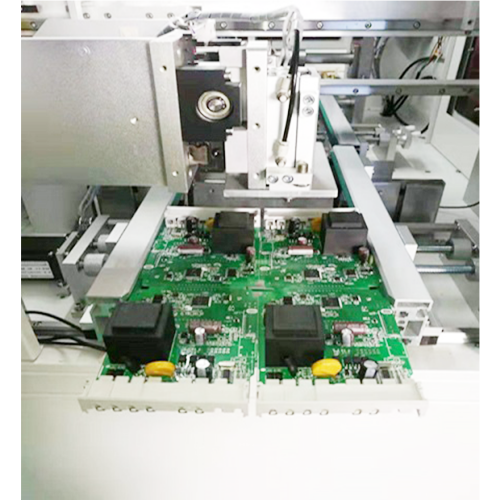

1. The PCBA board is sent out to the predetermined track through the upper board mechanism; the transportation track sends the PCBA to the top of the lower straight knife, the lower straight knife is raised, and the upper straight knife comes over to cut in the Y direction; follow the set cutting position and set Y All directions are cut completely.

2. The PCBA cuted in the Y direction flows through the track to multiple groups of multiple knives for one-time slitting in the X direction.

3. The cuted PCBA products fall onto the discharge conveyor belt, and flow into the next station through the conveyor belt.

Remarks: A piece of small circuit board that has been cut can be connected to the pick and place in tray machine.

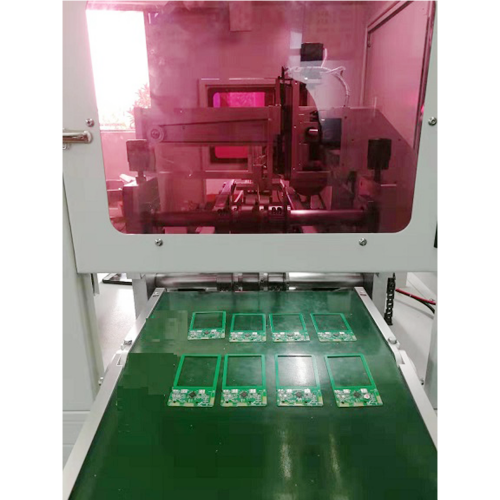

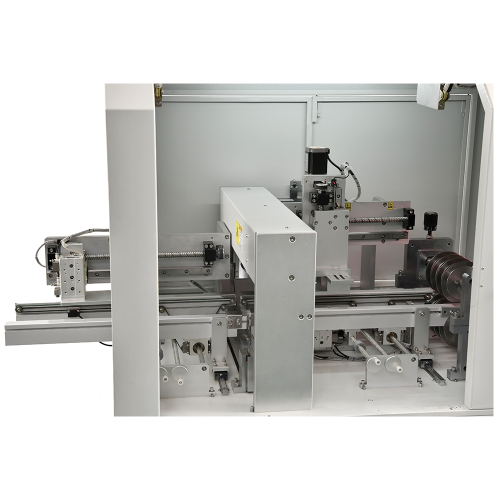

Brief description of the machine

Fully automatic on-line V-slot splitting machine has further improved the quality of splitting; it can realize the automatic splitting of V-slot X and Y directions, and split aluminum substrates, copper substrates, FR4, fiberglass board is cut clean and free of lint, and the splitter can be connected to the assembly line to realize automatic splitting without manual placement; the split boards are transported through the assembly line, which greatly saves manpower and fully realizes unmanned splitting operations.

Features

I .The equipment adopts a single group of multi-knife automatic splitting, making different knives according to different products. And it is convenient and quick to change products;

2. The electrical control part can be selected in the human-computer interface, which is convenient to open or shield;

3. Human-machine interface, light curtain form and acrylic cover are used on the table to ensure safety;

4. Can be equipped with a dust suction device according to customer requirements;

5. Floor-standing structure is adopted as a whole;

6. The frame of the automatic line equipment adopting square steel welded frame,sheet metal sealing plate,surface baked steel paint;

7. The work surface of the equipment is made of 45# steel plate or A L6061 aluminum plate;

8. The equipment is suitable for all jigsaw panels with V grooves;

9. Cutting material: fiberboard, aluminum substrate, copper substrate;

10. Data monitoring system: boot time monitoring .capacity monitoring, equipment failure information and automatic rejection system, etc.;

11 .Cut-board working method: use board feeder or direct suction cup to connect the assembly line to feed or suck PCBA into the sub-board mold. After the mold is installed, go through the set program route and follow the V-slot of the PCBA splicing board to finish. After slitting, the product and waste are sucked away by suction cups at the same time. The waste material is sent to the waste frame, and the product is sent to the tray on the assembly line and sent away. Fully realize unmanned production in cyclic operation.

Technical parameter

1.设备外形规格

机器名称Machine name

全自动在线V槽双方向分板机Full automatic on-line V-slot two-way board splitting machine

机器型号Machine model

XJVC-12A

外形尺寸Overall dimension

L*W*H=1720*800*1650MM

外形appearance

立式vertical

重量weight

600KG

颜色colour

电脑白Computer white

2.设备供应要求

电源供应Power supply

AC220V 2000W

环境要求Environmental requirements

清洁干燥环境,避免潮湿或高温Clean and dry environment and avoid humidity or high temperature

工作气压/管径Working pressure / pipe diameter

≥0.6MP/8MM

零件离切割线最小距离Minimum distance from part to

≥1.5MM

最大最小分板长度:Maximum and minimum partition

300*300MM 12*12MM

进板口调节board inlet adjustment

前侧固定,后侧活动调节(Front fixed, rear movable adjustment)

PCB板元器件最高高度Maximum height of PCB

PCB反面零件限高20MM,正面限高为35MM(The height limit of PCB reverse side parts is 20mm and the height limit of front side is 35mm)

3.设备软件部分

控制器Controller

PLC

参数设置Parameter setting

根据V槽的尺寸触摸屏直接输入According to the size of the V-slot, it is input directly from the touch screen

储存模块Storage module

可储存50组程序It can store 50 groups of programs

触摸屏touch screen

威纶触摸屏WEINVIEW touch screen

光纤传感器Optical fiber sensor

欧姆龙OMRON

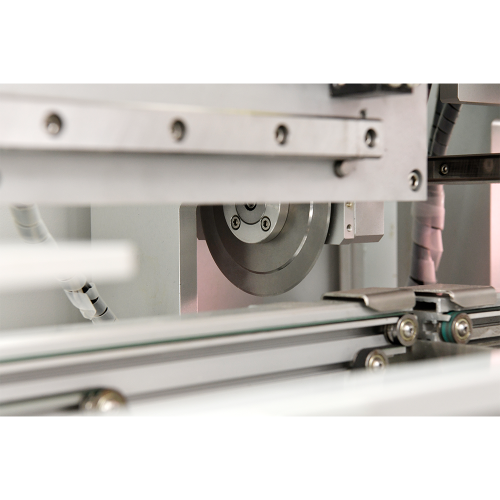

4.刀片

金属属性Metal properties

日本进口高速钢High speed steel imported from Japan

刀片角度Blade angle

10-30度(可选择)10-30Degree (optional)

使用寿命service life

5KM

刀模精度Knife mold accuracy

0.1MM

5.主控分板系统

分板效率Board splitting efficiency

25s/PCS(200*150mm)标准速度切4刀为参照(25S / PCS (200 * 150mm) standard speed cutting 4 knives as reference)

步进伺服器Step Servo

山浓/松下(SANNOON/PANASONIC)

导轨丝杆Guide screw

上银导轨丝杆HIWIN guide screw

气动配件Pneumatic accessories

AIRTAC/SMC

流水线最大长宽Maximum length and width of pipeline

650mm*250mm(可订制customizable)

分板速度Board splitting speed

0-800mm/s

吸盘机械手运动控制方式Suction cup manipulator motion control mode

步进马达+导轨+皮带传动Stepper motor + guide rail + belt drive

吸尘方式及效率Dust collection mode and efficiency

刀组下吸尘15Q0W(Dust suction under knife set 1500W)

分板厚度Thickness of slitting board

0.4-3.5mm

6.其他功能

误操作防护Misoperation protection

光栅传感器及软件三重防护Triple protection of grating sensor and software

零件表面处理Part surface treatment

阳极电镀Anodic plating

安全防护safety protection

急停Emergency stop

断电断气功能Power off and gas cut-off function

有yes

自检功能Self checking function

开机时间监控,产能监控,设备故障信息及自动排异系统

设备主要部分main part of the equipment

送板机(流水线),吸盘,三轴移动分板平台,吸尘器

工作方式operation mode

自动机械手在线分切送板Automatic manipulator on-line cutting and feeding board

适用范围Scope of application

插件/贴片后PCB板的双方向V槽Two-way V-slot of PCB after plug-in / SMD

Equipment appearance specifications

equipment supply requirements

equipment software

blade

Main control cut-board system

other functions

Startup time monitoring, capacity monitoring, equipment fault information and automatic rejection system

board loading machine (assembly line), suction cup, three-axis moving board splitting platform, vacuum cleaner

Contact me

Company : Guangdong Xiangjie Intelligent Technology Co., Ltd.

Address : No.105,Langbei Road,Changhuang Road,Changping Town,Dongguan City,Guangdong Province,China

Zip Code :523570

Email : alanhe@smtxj.com

whatsapp :+86 13650031915

Tel/Skype :+86 13650031915

website : http://www.xonje.com/en/

Facebook :https://www.facebook.com/profile.php?id=100072842804069

Youtube :https://youtube.com/channel/UC9gheGcXnZrYsP3k5PPoqJg

Shop :https://xonje.m.en.alibaba.com